#Copy monitor revit update#

Revit 2017.2.3 Update MEP Phasing Issue Fixed!.The existing levels and views will then be re. Enscape Blog Post: Best Practices for Lighting and. Now from the Copy/Monitor Ribbon select the Copy command and pick all of the story levels from your link.Dell Video: LHB visualizes architectural designs t.Reflecting on BILT-EUR 2017 in Aarhus Denmark.In Week 1, well cover the key aspects of. Watch My NVIDIA Webinar on VR in the AEC Space Video created by Autodesk for the course Autodesk Certified Professional: Revit for Structural Design Exam Prep.

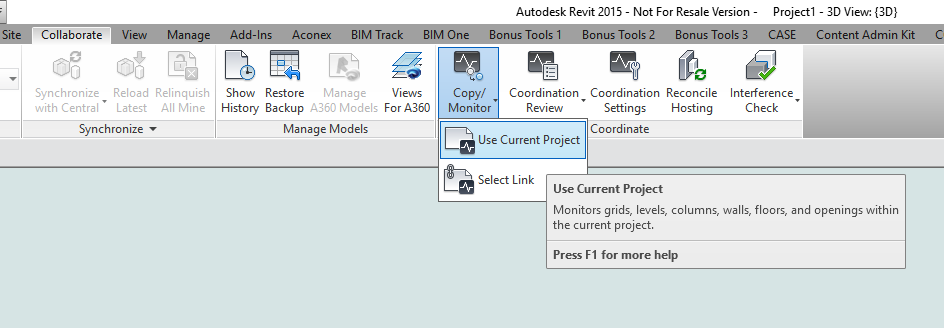

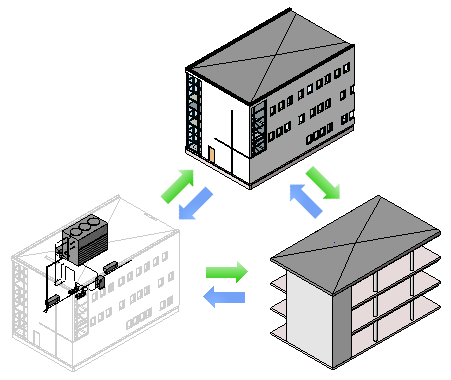

In my experience, most BIM projects have a separate structural model. It has some pros and cons, which I will highlight in the next few posts. This is a feature I recommend be used on every project in the multi-discipline firm I work for. But I just can’t wrap my head around how I can match up the equipment in my linked model to the copy/monitored equipment in the electrical model in order to set the parameters.I find that even experienced Revit users are not too familiar with Revit's Copy/Monitor feature. The Copy/Monitor command enables Revit to copy elements from a linked file and monitor whether these elements change. So far, I’ve managed to pull the information from my linked model. from my model, and sets this information the the respective copy/monitored equipment in the electrical model. So basically, in dynamo, I want to run a script that collects Type Mark, Mark, Voltage, Phase, etc. So in a job where the electrical team needs to circuit 700 of my fan powered boxes, each with a different Mark designation, and the possibility that this Mark may change or the electrical characteristics of the equipment may change, you can see where the tedious work will start. I’ve learned the hard way that a) instance parameters do not transfer when a piece of my equipment is copy/monitored in the electrical model, b) if I make a change to (example) voltage in my model, the change is not reflected in the copy/monitored equipment in the electrical model. A perfect example of the collaboration tool. The electrical team then copy/monitors my equipment into their model in order to circuit it to their panel and also populate their schedules. In my mechanical model, I tag my equipment by Type Mark and Type and then add all the associated electrical data to the equipment which is also shown on my schedules (voltage, phase, frequency etc.) I work in an MEP consulting firm in which (for the majority of larger projects) we split up models by trade. Sorry I’m unable to post a screenshot but hopefully my explanation will suffice.

0 kommentar(er)

0 kommentar(er)